Disclaimer: All the logos and artwork belong to their respective brand. we don’t take responsibility for any of the logos shown in the images. The images are just for representation purposes.

Why Laser marking on ABS/NYLON/ SILICONE/PE/ FLURO CARBON RESINS is a big challenge?

- It does not give high contrast with conventional Laser Marker & engraver.

- Requirement of additives in masterbatch which are not safe for plastic products in the food industry.

- The surface of the part alters. Peripheral heating also occurs which damages the surface of the part.

- The system is quite expensive with poor quality marking.

The answer to all of the problem lies in Markolaser’s UV 355, UV laser marker

- Markolaser’s UV laser marking system gives extremely high contrast and sharpness.

- Has a minimal footprint due to the compact design of UV laser marking machine.

- Is stable & durable in operation which UV laser marking on plastic and Metals.

- 12 months Warranty from the date of invoice.

- Option of an air-cooled system for industrial temperature >32 ° C.

- Easy to integrate on automatic lines.

- Markolaser’s “follow the curve” of UV 3D system works very well on curved parts.

- This is very important on curved parts as the depth of focus of UV lasers is generally very short.

- Markolaser UV series is easy to integrate into automatic lines.

- Our Versatile MTrack software can be easily customized and integrated as per the client’s

requirement.

355 nm wavelength lasers from Markolaser gives extremely high contrast and sharpness. The difficult to mark plastics absorb UV wavelength and create marking by photochemical reaction, which is very smooth.

This UV marking Laser is also called ‘Cold marking’.

The laser marking by Markolaser UV 355 system is so smooth yet with high contrast , that it cannot be felt by touch.

What are the Industries where UV lasers are used?

- Household machines like washing machine, dryer, coffee machine front panels.

- UDI UV Laser marking for Medical industry – Earbuds, Biomedical & Bioengineering.

- Electronics – Earphones, Charger for Branding, Logo UV engraving and Technical Specification engraving on Plastic.

- Electrical – MCB UV Marking.

- Traceability(Trace and trace ), compliance and identification marking- high-quality machine-readable alphanumeric characters, 1D/2D barcode and Datamatrix Unique code, logos, insignia etc. on plastics and composites.

- Designing of Creative Art and Soothing classy Grey marking.

- Pharmaceutical Traceability code, Expiry dates and MRP.

- UV Laser for Semiconductor processing.

- Trace and Trace the composition and date of manufacturing of Closures, crown caps.

- Hight speed UV laser Marking of Price and expiry dates on Packaging and FMCG.

Highly Legible and high Contrast UV Laser Maker and engraving Machine

Introducing Eminent – Brilliant 3-Axis Control UV laser Engraving Machine

UV (ultraviolet) lasers Marking, Unique and premium laser Marker and engraver

Clean and Clear

Sharp and Premium detailed High Dark and Contrast UV Marking.

Decreases heat effect on the Metal and Plastic Components. Results in Damage-Free annealing or foaming i.e Marking

Damage-free

UV marking with reduced heat effect Zone.

The Markolaser UV series delivers more contrast for more attractive visuals and better improved appealing aesthetics and readable 2D code. Burrs and yellow tinting are reduced due to reduced heat effects, resulting in a flawless finished surface.

Eliminated/ Distortion-free

3D UV Laser Marking

High-Speed UV Marking, Increases Manufacturing Capability Not only on three-dimensional shapes, but also at the centres and edges of flat surfaces, uniform labelling accuracy is possible. This reduces the amount of time spent on changeovers.

Incremental production capacity

Superfast UV Marking

The patented(German) optical scanners from Markolaser Solutions have been designed for more precise and quicker Marking.

High Contrast UV laser Marking

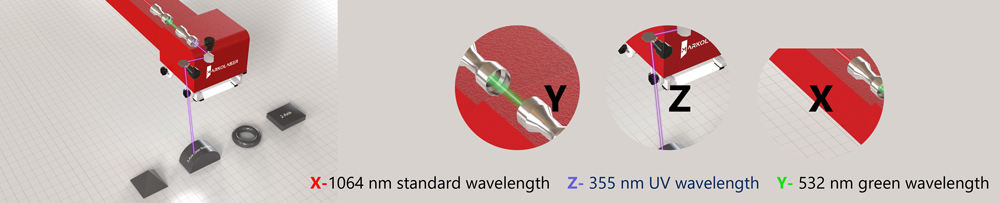

UV lasers have a significantly higher substrate absorption rate than typical wavelength lasers (IR/1064 nm) and green lasers (SHG/532 nm), allowing effective absorption of emitted light by the labelling film. It ensures that the strength doesn’t have to be boosted in order to make extremely noticeable marks.

Damage free UV Laser marking

UV laser marking Gives us the advantage of high absorption rates even with high reflectance metals like gold, silver, copper, and other metals, resulting in minor heat damage. It reduces soot and burrs even while eliminating surface degradation, allowing corrosion-resistant UV Laser marking and processing.

Over time, the scale of electronic components has shrunk, and the sealing resin has become thinner as well. Harm to internal components induced by energy transferred through the sealing resin has become a real problem for normal wavelength lasers. UV lasers have a high material absorption efficiency, which decreases the risk of energy being transferred to internal materials.

Value Addition With MARKOLASER’s Markolaser UV series UV Laser marker and engraver

- Enhanced Traceability (trace- Grade- track)

UV Laser Marking on a large variety of products, instead of the finished product, has become increasingly popular. With the Markolaser UV series, your choices are almost limitless.

- No problem with a limited amount of space.

With a growing need to minimize part size while increasing versatility, the Markolaser UV series offers greater durability by damage-free UV marking in confined and in very little spaces.

- Incremented Possibilities with Difficult Substrate

High-power, high-heat resins have traditionally been difficult to work with, with regular wavelength lasers. The Markolaser UV series provides best-in-class flexibility across a broad range of substrate types

- Reduced Changeover: Increased Efficiency

Many substrates may be marked with the same parametric specifications, limiting a need for operator(engineer) interference and increasing line up-time and performance.

UV Laser Marking Vs Conventional Laser marking Sampling

Laser Marking on Automotive component

UV laser

Conventional Laser

Laser Marking on Plastic Bottles

UV laser

Conventional Laser

Laser Marking on Tubes and Plastic Wires

UV laser

Conventional Laser

Laser Marking on Plastic Automotive Switch

UV laser

Conventional Laser

Laser Marking on Green Plastic cap (Autopart)

UV laser

Conventional Laser

Disclaimer: All the logos and artwork belong to their respective brand. we don’t take responsibility for any of the logos shown in the images. The images are just for representation purposes.