Laser Marking Machine for Plastic & Metals

Laser Marking on Plastic & Metals

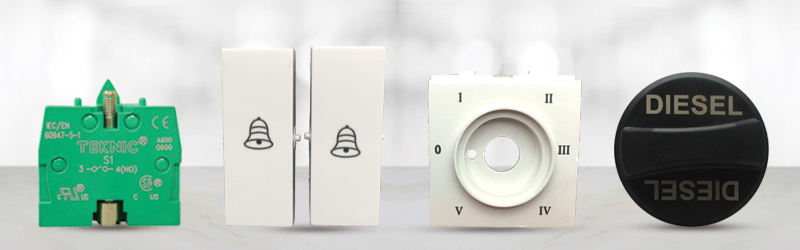

Plastics is one of the essential element of industry and laser marking on the material or product made up of plastic has become essential for branding/ laser printing of logo and to identify that plastic product, it may be your grinder or your dryer, laser marking is done to put labels of manufacturing dates and data matrix code. The different source is used for marking on a different type of material and plastics.

Markolaser is the manufacturer of Laser marking machine for all the types of Plastic example like ABS, PP, PET, NYLON-66 or PA, etc all these material will react differently with different laser sources and machine.

The very fundamental difference between laser marking and printing with inks by pad printing machine or screen printing machine is that Laser printing is permanent whereas Printing with a pad printing machine or screen printing machine can be easily erased by using abrasion solution. Although the printing will look dark for some days but will fade with time. On the other hand, the laser marking on plastic will remain highly contract even after 100 years.

Laser Technology

CO2 laser, GREEN laser, YAG YVO4 laser:

Applications on Plastics

Laser Marking on ABS:

Laser Irradiation from the laser Marker results in a visible white colour on the surface of the plastic. Laser Marking on the plastic surface results in printing like feeling the artwork, symbol, any logo or any alphanumeric character cannot be erased.

Laser marking on Nylon

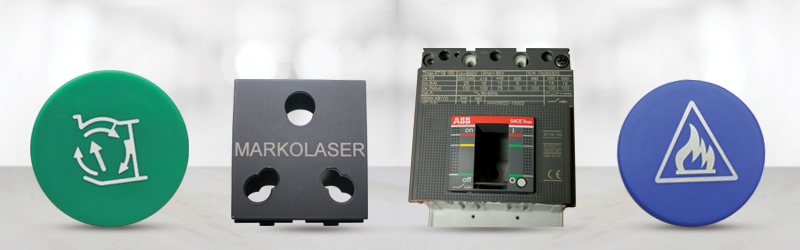

Laser marking of Electrical rating on MCB with UV laser marker gives a perfect Contrast on the surface of MCB

Laser Marking on Epoxy Plastic

Laser marking on Electrical chip for identification and label marking of manufacturing date and MRP is made easy by markolaser marker

Laser Paint Removal from PP Plastic

Laser tapes are available in the market, the marking process is very easy because the laser maker removes the paint of those plates and let the layer under that visible

Laser Marking Application on Metals:

Internal Process Traceability (With Traceability Software and Traceability Laser Marker):

By laser marking, we can automate the complete production processes and optimizes it well and that will helps meet standards requirements.

Product Identification till it gets Recycled or Decomposed/Discard:

Permanent Laser marking of Data matric code makes the product unique to trace and track throughout the life cycle which further gives product complete information and instructions, 2D code reader and validator helps to extract data.

Personalisation & Branding(Logo and Artwork Marking):

Permanent logo on the product gives a premium feel to the part. And beautiful artwork makes it more beautiful.

For more info : Contact Us