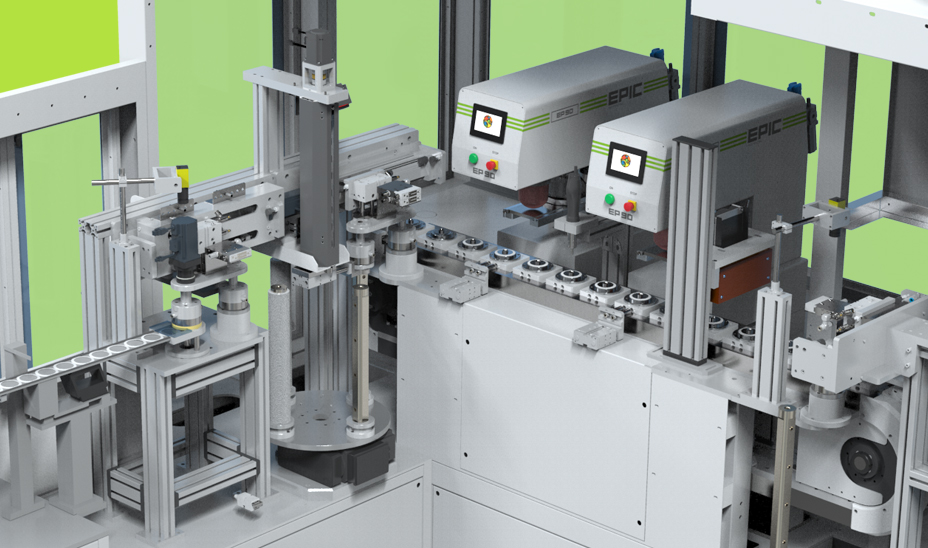

Easy integration into automation

EPIC Pad Printing Machines are a range of European-inspired equipment with sleek and efficient designs, specifically tropicalized for the Asian environment. These machines are engineered for high energy efficiency and occupy minimal space, yet deliver outstanding performance in terms of speed, pressure, and accuracy, whether for single or multiple prints. They can easily integrate into automation systems via D-SUB 37 PINS and offer a wide range of options, including indexers, pre- and post-substrate treatment modules, ink residue pick-up modules, viscosity measurement, and thinner metering pumps. If you're seeking a solution that delivers exceptional results with the efficiency and precision demanded by the industrial sector, EPIC Pad Printing Machines are the perfect choice. (Patent pending no. 202311029799)*

Salient features & advantages

|

Compact, simple and environmental friendly machines. |

|

Low ink consumption - Start with ink mixture as low as 15 grams (60 cup). |

|

Electro-pneumatic drive with PLC control and finger touch HMI from Europe. |

|

Excellent and precise registration of image, each and every time. Thanks to its high end milled parts in very hard & tempered metals |

|

High speed with sharp printing. |

|

All critical components from EUROPE. |

|

Highest tampon pressure in a similar sized machines to use 22 shore A silicone rubber pads. Generally harder pads give better print quality |

Other features

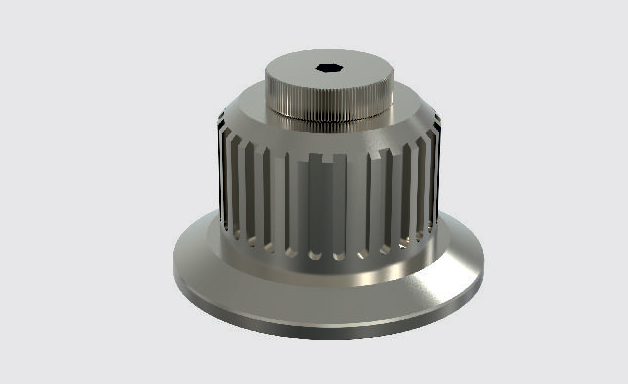

- Non-magnetic ink cup rings of 80 HRC hardness of tungsten carbide or high-tech ceramic as an alternative

- Ring can be changed once worn off.

- 37-pole automation interface allows addition of indexers, etc.

- Low energy consumption.

- Multi print functions: Two pickups one print or just a cycle of two, three prints lets you print on dark and/or absorbent surfaces

- Variable contact pressure on ink cup to reduce friction on cliché.

Pad Printing on Cosmetics

Excellent multicolor printing on complex shapes

Pad Printing on

Tap

Consistent repeatability with exellent sharpness

Pad Printing on

Glass

Excellent registration on convex / concave / cylindrical / uneven surface

Pad Printing on Garments

High ink deposition for high opacity printing

ELECTRO-PNEUMATIC INK CUP SERIES

Standard Pad Printing Machine

Optional Model

TCS - Tape Cleaning System (Optional)

Our new and improved programable Tape Cleaning System is designed to remove ink residue and dust from the pad surface, ensuring consistent and accurate printing. It is a valuable addition for industries that require precise and multiple prints