Our Lifestyle requires products that are easy to use, convenient, appealing to the senses yet environment friendly at the same time.

The plastic or metallic caps and closures is a packaging component that is used for an easy to open/dispense packaging, for prolonging the shelf life of the contents with an airtight seal/cap/ closure, protection against dirt, moisture and other contaminants and preventing the product from getting damaged.

Closures can be caps, seals, covers, lids or plugs , whatever is suitable depending on the material, type of packaging and economies of the product manufacturing. The potential applications of caps and closures in packaging include Food and beverage like soft drinks, juices, dairy, still water caps, Glass bottle lids and spouts, over caps, lids and cosmetic caps, crown caps, bottles, tubes and flexible packing, ketchup bottles, wine & liquor sector, shoe polish lids, in bottles, tubes and flexible packaging, flip top caps and many more.

The plastic caps are generally made of PP, PE, HDPE, LDPE/LLDPE POLYMER and ETP plastics whereas metallic caps are visually very attractive made from pilfer proof aluminium sheets for tall caps, ROPP caps with steel finish, tin plate Twist/lug closures, baby food BRP closures and other materials.

Printing Technologies for Caps and Closures

Printing on caps/ closures is a very interesting subject as many technologies can be used for decoration of caps for branding, identification, information, boosting shelf impact, driving sales, promotions and building brand loyalty.

- Screen printing on plastic and metal caps is a technique to transfer a design with highly opaque inks on the surface of the closure using silk screens. The effect is a highly glossy impression that can be felt on touch giving a the beverage cap a stunning look.

- Offset printing on bottle caps and closures uses two rollers to transfer the image onto a flat cap. This bottle cap printing technique is cost-effective.

- Inkjet digital printing is efficient for small quantities of printing on plastic caps and metal caps, generally used in promotional printing.

- Hot stamping and heat transfer can be performed on curved and convex surfaces of various shapes and sizes. In this cap decoration method, a hot stamping die is made with the desired design and pressed against the closure, with a foil sandwiched in between. With heat, pressure, and contact time, the foil adheres to the cap, giving it a luxurious metallic finish. This technique usually applies one foil color at a time and is popular for premium bottle closures.

- Kiss printing (highlighting) involves transferring colored ink to an embossed bottle cap or closure using a roller. This enhances raised designs and adds visual appeal to the cap printing process.

- Embossing and debossing are performed during the molding of closure caps to create attractive 3D designs on the surface. This technique improves branding and adds a premium look to plastic and metal closures.

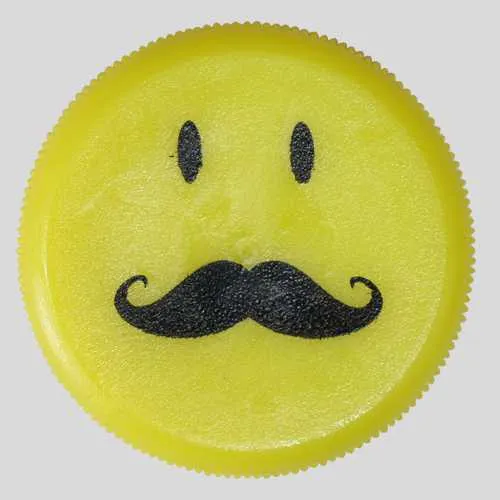

- Pad printing on caps and closures makes printing of 1–6 colors on caps of different sizes. This pad printing technique offers sharp image registration, superb print quality, and long-lasting prints due to high ink deposition. Even the smallest letters can be printed very sharp. Quick changeover times make pad printing one of the most preferred bottle cap printing methods.

- Laser marking on caps and closures is a high-contrast, additive-free marking technology used for marking QR codes, logos, and specific alphanumeric codes on the inside or outside of plastic closures, plastic caps, metal caps, and crowns used on PET bottles, aluminium screw caps for glass bottles, aluminum foil lids for food cartons, sheet-steel screw caps, and synthetic wine corks. This laser marking process ensures strong anti-counterfeiting protection and is ideal when each crown, cap, or closure needs to be marked with different data to generate unique promotional codes and characters. The marking is very sharp, tamper-proof, food-safe, and extremely fast. It is usually an inline process where the data is fetched directly using special software. This high-speed method is also known as “mark on the fly” laser marking.

What does Spinks World offer for printing and decoration solutions on Closure and Bottle caps Industry

Machines for printing and marking for the Closure and Bottle caps Industry

EPIC Pad Printing Machine

EPIC Pad Printing Machine

EPIC Pad Printing Machine

Compact, simple, and environmental friendly high pressure pad printing machines

Markolaser Machines

Markolaser Machines

Markolaser Machines

Laser marking/ engraving machines for marking on Closure and Bottle caps Industry

Printing ink solutions for Closure and Bottle caps Industry

Ruco Inks

Ruco Inks

Caps & closures of soft drinks, bottle lids, tubes, cans

Beverage and Brewery industry, Liquor, wine, flexible packaging caps

Farbatech Inks

Farbatech Inks

Bottle closures, Metallic caps, Rigid PVC and HDPE

Medical, FMCG, Beverage, Liquor, Household, Cosmetics, Glass, Plastics

Consumables for Closure and Bottle caps Industry

Silicone Pads

Silicone Pads

Silicone Pads

Special silicone pads are used in the pad printing to transfer the precise, sharp & high resolution image from the cliche to the surface to be printed. ...All silicone pads are readily available on demand as they are "Made in India" with International standards.

Cliché Plates

Cliché Plates

Cliché Plates

Cliché Plate material, depth, size, toughness, lapping & etching and grounding are some key factors that make it perfectly suitable for pad printing ...based on the application for excellent printing results.