What is Screen Printing?

Screen printing or silk screen printing is a popular printing technique where a mesh (screen made of silk) is utilized to transfer the design onto the substrate surface such as fabric, paper, glass, metal or plastic.

The mesh is composed of synthetic polymers including nylon and polyester. Screen printing is a direct printing process in which a blade and squeegee are utilized in transferring the stenciled pattern on the desired surface or substrate. It’s a flexible process that can be done on numerous surfaces havingdistinct shapesand sizes.

Mesh screen and ink plays a salient role in creating design on the required surface. The process includes generating a stencil on mesh (screen) and creating the design on the required surface with ink. Screen printing is a technique that is widely chosen by various industries due to its superior outcomes and attractsindustries as it hasmultiple options of colors that can be utilized in this process.

Why Screen Printing?

Screen printing offers several advantages over other printing techniques that make it a preferred choice for many applications.

Versatility: Screen printing can be performed on a wide range of materials, including textiles, ceramics, glass, metals, and plastics, making it a versatile printing method.

Durability: The inks used in screen printing are typically highly durable and resistant to fading, making the printed designs long-lasting and suitable for items that require frequent use or washing.

Vibrant Colors: Screen printing allows for the use of vibrant and opaque inks, resulting in bold and eye-catching designs that stand out.

Cost-Effective: Screen printing is often cost-effective for large production runs, as the setup costs can be distributed over a larger number of printed items.

Applications of Screen printing

Screen printing finds various industrial applications due to its versatility, durability, and ability to produce high-quality prints. Here are some notable industrial applications of screen printing:

- Custom Apparel: Screen printing is a popular choice for creating custom t-shirts, sweatshirts, hoodies, and other types of apparel. It allows for high-quality and durable prints on fabric.

- Promotional Items: Screen printing is often used to create promotional products such as tote bags, caps, pens, and other merchandise for marketing and branding purposes.

- Signage and Posters: Screen printing is suitable for producing large-scale signage, posters, and banners with vibrant colors and long-lasting quality.

- Electronics and Circuit Boards: Screen printing is extensively used in the electronics industry for printing conductive inks and creating circuit patterns on printed circuit boards (PCBs). It allows for precise deposition of conductive materials, such as solder masks, etch-resistant inks, and component legends.

- Automotive Components: Screen printing is employed in the automotive industry for marking and decorating various components. It is used to print labels, logos, and instructions on engine parts, dashboard panels, instrument clusters, and buttons. Additionally, screen printing is utilized for printing conductive materials in automotive touchscreens and sensors.

- Appliance Panels and Controls: Screen printing is commonly used in the production of appliance panels and controls. It allows for the application of functional and decorative prints on control panels, buttons, and displays. Screen printing is also used to print labels and safety instructions on home appliances.

- Aerospace and Defense: In the aerospace and defense sectors, screen printing is utilized for marking and labeling aircraft and defense equipment. It provides durable and long-lasting identification markings on metal, plastic, and composite materials used in aircraft components, instrument panels, and military equipment.

- Industrial Labels and Identification: Screen printing is employed for creating industrial labels and identification tags used in various industrial settings. It allows for the printing of barcodes, serial numbers, product information, and safety warnings on metal, plastic, and other materials.

- Membrane Switches: Screen printing is a preferred method for producing membrane switches used in control panels, keyboards, and touch-sensitive interfaces. It enables the precise deposition of conductive inks and overlays on flexible substrates, resulting in reliable and functional switches.

- Solar Panels: Screen printing is widely used in the production of solar panels. It allows for the application of conductive pastes and inks on solar cells to create electrical connections and form circuitry patterns. Screen printing ensures accurate alignment and deposition of the conductive materials, contributing to efficient solar cell performance.

- Screen printing is extensively used in the footwear industry for customization, branding, and design. It allows for personalized shoe graphics, including logos, patterns, and text, enabling consumers to create unique designs. Brands utilize screen printing to apply logos and branding elements, establishing brand identity and recognition. Textile printing on shoe uppers,Insole printing provides functional information and enhances brand visibility. Special effects and finishes, such as metallic inks and embossed textures, enhance the visual appeal of shoes.

Plastic Substrates on which Screen Printing can be done

- ABS

- PMMA

- PA

- POM

- PVC

- PC

- PU

- PS

- CAB

When screen printing on plastics, it's important to consider the specific characteristics of the plastic substrate, such as its surface energy, texture, and compatibility with inks and adhesion promoters. Proper surface preparation, such as cleaning, priming, or using adhesion promoters, may be necessary to achieve optimal ink adhesion and durability. Sometimes post curing is also required during screen printing for heightened effects.

Metal substrates on which screen printing is usually done

- Stainless steel

- Powder-coated metals

- Painted and anodized metals

- Cast iron

- Aluminum

- Brass

- Bare or varnished metals, and more

These metals are compatible with the screen printing process, allowing for the application of custom designs, logos, and other graphics onto their surfaces.

Besides these screen printing can be readily done on cloth materials, leather and glass.

Key Elements for a Successful Screen-Printing Process

- Screen Printer and Consumables: The primary tool for screen printing is the screen printer itself, which consists of a frame, mesh screen, and a squeegee. Additionally, various consumables such as emulsion, stencil films, and cleaning chemicals are needed to prepare and maintain the screens for printing.

- Screen Printing Inks: High-quality screen printing inks are essential for achieving vibrant and durable prints. These inks come in a wide range of colors, including standard, metallic, and specialty options. Different types of inks are available based on the printing substrate, such as textile inks for fabric and solvent-based inks for plastics or metals.

- Pre-Press Treatments: To ensure optimal adhesion and longevity of the prints, certain pre- treatments may be necessary. This can include applying adhesion promoters or primers on specific substrates, using a pre-coating or pre-treatment for textiles, or employing stencil techniques to create precise and detailed designs.

- Curing and Drying Equipment: After the prints are applied, curing and drying the ink is crucial to achieve proper adhesion and durability. Depending on the type of ink, a heat source or UV curing equipment may be required to ensure that the prints are fully cured and ready for use.

- Quality Control Tools: To maintain consistency and accuracy, various quality control tools are used in screen printing. This includes measuring and adjusting the tension of the mesh, monitoring and maintaining the ink viscosity, and inspecting the final prints for any defects or inconsistencies

By having these essential elements in place, screen printing professionals can ensure a smooth and successful printing process, resulting in high-quality and visually appealing prints.

Spinks World is your one stop reliable source for all your screen printing needs, providing:

- Cutting-edge screen printing machines

- Expertise in screen printing frame development

- High-quality screen printing inks

- We are here to assist individuals and businesses seeking effective screen printing solutions.

We are here to assist individuals and businesses seeking effective screen printing solutions.

Screen printing solution product portfolio from Spinks World

Screen Printing Machines

At Spinks World, we offer advanced screen printers and automation solutions designed for high-speed production. Our range includes state-of-the-art fully automatic and semi-automatic screen-printing equipment equipped with modern features to enhance efficiency and productivity.

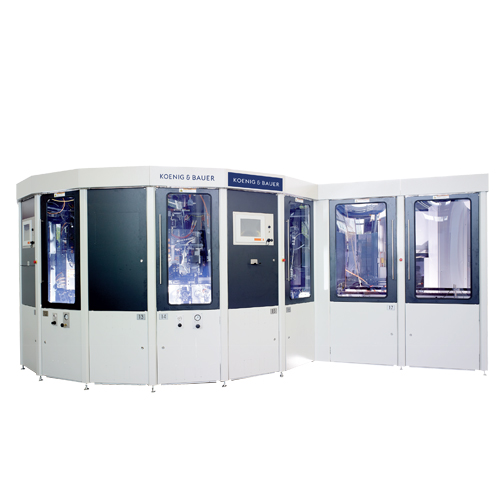

KAMMANN

Spinks represents Koenig & Bauer, AG, which is a leading German company in the printing industry as their representative in India. It is one of the oldest printing machinery manufacturers globally, with a history dating back to 1817. Koenig & Bauer specializes in the design, development, and manufacturing of Screen printing machines and related equipment. They offer a wide range of solutions for various printing applications, including packaging, commercial printing, security printing, and industrial printing. Koenig & Bauer is known for its technological innovation, exceptional quality, and precision in screen printing machinery, and it serves its customers worldwide.

Koenig & Bauer is widely recognized as one of the most successful global leaders in the decoration of containers and hollow glass ware for various industry sectors like glass, packaging, and plastics. Read more ...

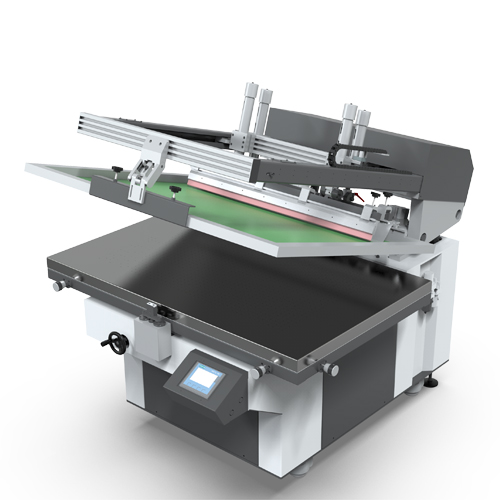

SUKURIN

Experience the rapid growth of Sukurin screen printing machines, delivering cutting-edge screen printing technology and exceptional results. Our machines are equipped with advanced features that ensure precise color-on-color registration for multi-color printing. Additionally, we offer comprehensive in-house solutions including pre/post treatment options and a wide range of industry-specific inks.

At Spinks, we take immense pride in the design and manufacturing of Sukurin machines. We utilize high-quality components to optimize productivity and achieve top-notch outcomes. Our machines are not only renowned for their superior performance but also for their versatility in customization, tailored to meet specific requirements. While we offer standard machines suitable for diverse industries, we also provide customized automations to cater to the unique needs of our valued customers. With Spinks industrial screen-printing machines, expect exceptional performance and unwavering reliability. Read more ...

Screen Printing Inks

Screen printing inks are specifically formulated for the screen printing process, and they possess unique characteristics that make them well-suited for this application. These inks play a crucial role in producing high-quality results across various industries. As a leading provider of screen printing inks, Spinks World is committed to developing inks that undergo extensive research and expertise. We prioritize quality and strive to deliver highly effective, brilliant, and long-lasting results.

Our screen printing inks have undergone rigorous testing to ensure they meet the specific requirements of different industries. We understand the importance of efficiency in the printing process, which is why our inks are designed to dry quickly.

With Spinks World's screen printing inks, you can trust in the reliability and performance of our products, backed by our dedication to quality and customer satisfaction.

Features of Screen Printing Ink

- One/two component inks

- Durable inks

- Color range and specialty effects such as glow in the dark, thermochromic photochromic and textured inks.

- Able to print difficult products

- Highly opacity, high coverage and good adhesion

- High reactivity

- Weather resistance

- Mechanical and chemical resistance

- High viscosity

- Compatibility with various substrates

- Specially formulated for different curing methods

Overall, screen printing inks are specially designed to meet the specific demands of the screen printing process, providing excellent viscosity, opacity, durability, color range, and compatibility with various substrates. Their unique characteristics make them an ideal choice for achieving high-quality, vibrant, and long-lasting prints in the screen printing industry.

Types of Screen-printing Inks

Solvent-based inks

Solvent-based screen printing inks can be utilized for numerous substrates. The inks require additives such as thinners, hardeners, or retarders. Our in-depth knowledge , years of experience and advanced printing solutions make us printing industry specialists

UV inks or UV curing inks can be used for plastics, wood, glass, metals, ceramics, mobile phones, etc. Special effect inks meet ROHS and REACH standards and can be used for Silk screen printing, Pad Printing, spray coating, digital printing, etc. Some additives are also added for splendid results.

UV LED curing inks

UV screen printing or LED curing is the latest technology that has various benefits like high printing speed, saving energy, etc. This method is preferred over traditional mercury light curing. These inks can be used on high-speed screen printing machines as well.

Discover the Vibrant World of screen printing Inks: with Spinks World!

Your Ultimate Hub for High-Quality Screen Printing Inks sourced from Leading Global Suppliers. We offer tailored solutions for all your printing challenges, including our own range of specially manufactured inks and colors designed specifically for industrial screen printing applications. Trust Spinks World to provide a comprehensive selection of screen printing inks for diverse substrates and industries. These inks often meet stringent regulatory standards and can help businesses achieve their sustainability goals. Contact us for more details

Below is a list of screen printing inks in our portfolio.

Rucoinx

Spinks World is Your Source for High-Performance Screen and Pad Printing Inks from Rucoinx in Germany  . Our carefully selected inks are specifically designed to deliver outstanding printing outcomes on a wide range of substrates, including ABS, HDPE, PET, PC, PETG, PMMA, PP, Pre-treated HDPE, Pretreated OPP, PU, TC Polypropylene, and more. With their superior quality and impressive performance ratio, these inks guarantee excellent results and utmost satisfaction.

. Our carefully selected inks are specifically designed to deliver outstanding printing outcomes on a wide range of substrates, including ABS, HDPE, PET, PC, PETG, PMMA, PP, Pre-treated HDPE, Pretreated OPP, PU, TC Polypropylene, and more. With their superior quality and impressive performance ratio, these inks guarantee excellent results and utmost satisfaction.

Merlia

Spinks World is a dealer of merlia inks  in India Their comprehensive ink portfolio covers different printing techniques, including screen printing, pad printing, and digital printing. Whether you're printing on paper, textiles, footwear, sports goods, glass, plastics, or other substrates, Merlia Inks provides reliable and superior-quality solutions.

in India Their comprehensive ink portfolio covers different printing techniques, including screen printing, pad printing, and digital printing. Whether you're printing on paper, textiles, footwear, sports goods, glass, plastics, or other substrates, Merlia Inks provides reliable and superior-quality solutions.

Farbatech

Introducing Farbatech Inks  : Your Only Source for Unparalleled Solutions in Pad Printing and Screen Printing. Our exceptional range of technical inks offers a diverse palette of colors specifically tailored for industrial applications. Widely utilized in industries such as toys, glass, cosmetics, medical, automotive, apparels, and more, our screen-printing colors have become a top choice for professionals seeking compliant and high-quality technical inks to elevate their printing projects to new heights.

: Your Only Source for Unparalleled Solutions in Pad Printing and Screen Printing. Our exceptional range of technical inks offers a diverse palette of colors specifically tailored for industrial applications. Widely utilized in industries such as toys, glass, cosmetics, medical, automotive, apparels, and more, our screen-printing colors have become a top choice for professionals seeking compliant and high-quality technical inks to elevate their printing projects to new heights.

Inks covering various substrates are as below

Farbasil

Farbasil inks are silicone-based ink that proffersgreat durability. Used for printing on different substrates, user-friendly, easy to use, and hasmechanical strength. Speed up production and provide superlative results.

Farbatex

Farbatextagless printing ink series are predominantly two-component inks. Perfect choice due to great adhesion, high opacity, and different range of colors available. Safe to apply with zero skin irritation. These inks are oekotex level 3 certified.

Farbatone

Farbatone offers Pad printing and screen printing inks that are weather and scratch resistant and provide bright and precise results. Farbatone inks can also be utilized for making PU heat transfers.

Farbamed

Superior inks that are suited for medical devices, medical parts, toys, and baby products. Exhibit finest mechanical and chemical resistance. These are highly opaque and weather resistant. These inks are medical grade passing all the tests required by medical device manufacturing sector.

Japan Belleview

Their extensive range of inks covers various printing methods, including screen printing, pad printing, offset printing, and more. These inks are known for their exceptional performance, vibrant colors, and excellent adhesion on different substrates.

High-temperature glass printing inks are specifically designed to withstand the extreme heat required during the glass decorating process. Here are some key features of Japan belleview high-temperature glass printing inks.

- Heat resistance

- Excellent Adhesion

- Vibrant Colors

- Chemical Resistance

- Versatility

- Durability

- Compatibility

- Regulatory Compliance

It's important to note that different types of inks may require specific curing or drying methods, so it's recommended to follow the manufacturer's guidelines for optimal results. Additionally, it's advisable to conduct thorough testing on a small scale before proceeding with large-scale screen-printing projects.

Screen Printing Frames and mesh

Screen printing frames and mesh are essential components in the screen printing process, playing a crucial role in achieving accurate and high-quality prints.

Screen printing frames, also known as screens or frames, are rigid structures typically made of aluminum, wood, or steel. They provide a stable foundation for stretching and securing the screen printing mesh. The frame's size and dimensions depend on the desired print area and the type of printing application.

The screen printing mesh, on the other hand, is a finely woven fabric or polyester material stretched tightly over the frame. The mesh acts as a stencil or template through which ink is transferred onto the printing substrate.

Overall, screen printing frames and mesh are fundamental elements in the screen printing process, providing the foundation for achieving high-resolution, vibrant, and durable prints on a wide range of materials and products.

At Spinks World, we go beyond simply offering inks, machines, screen printing frames, and mesh. We are committed to providing comprehensive guidance on how to achieve the best results in your screen printing endeavors.

Contact us now, for more details